Quality Philosophy

In Quality Engineering, I believe understanding customer expectations is crucial to success. I also believe that everyone in the company is a part of the quality team and together we all drive quality. As such, I like to get right onto the floor and work with each stakeholder using a variety of tools when trying to truly understand opportunities, how they impact each one, and how effective the solutions are.

What Sets Me Apart?

I love Quality and Manufacturing, and as such, I have crafted my education, experience, and personality to succeed in these areas. With a degree that delves into a variety of disciplines and complex systems, I am able to work effectively with teams from a variety of roles. I bring a variety of classic Quality tools such as statistical process control and cutting-edge techniques like simulation and machine learning in creative ways to develop, refine, and modernize complex Quality Management Systems. With my 2 years of work experience (8 months in Operations Quality), Six Sigma Green Belt and other quality tools, awarded education crafted for Quality, and dynamic personality, I am the perfect candidate to drive Quality.

Well Rounded

Dynamic

Experienced

Moldable

Innovative

Quality Education

I graduated in June 2017 with a Bachelor of Applied Science in Honours Management Engineering at the University of Waterloo. This degree is focused on improving efficiency and effectiveness in a variety of disciplines. I crafted my degree with courses that focus on Quality Management, Control, and Assurance and Manufacturing. Through the Institute of Industrial and Systems Engineers, I also have my Green Belt in Six Sigma certification.

Quality Experience

I have 2 years of co-op experience, with 8 months at Rockwell Automation as an Operations Quality Engineer. During my term here, I used a variety of Six Sigma Quality tools including Statistical Process Control, DMAIC project management, Gauge R&R, and Measurement Systems Analysis. I worked directly with the teams on the floor, office, and management to gain buy-in and effectively reduce defects by 7%. I also participated in and often ran Material Review Boards, and acted as the Quality Representative for 9-Panel meetings.

While at Gyptech, I acted primarily as a Mechanical Design Engineer; however, I also created a custom tool to reduce design checking time and save approximately $1500 a month, mapped design processes, and improved their design time using a special Inventor tool.

As a teaching assistant, I was awarded for exceptional efforts while teaching students many of their fundamental Management Engineering concepts and Linear Algebra. Lastly, as a Manufacturing co-op at Centra Industries, I designed a system to reduce inspection costs and worked on various other continuous improvement initiatives from shop-floor employees.

Quality and Me

To start, I love quality engineering! Ever since I took my Six Sigma Green Belt Certification course with the Institute of Industrial (and Systems) Engineers I was hooked. I had the opportunity to apply those practices to my work at Rockwell Automation Inc, which motivated me to go a step further and take a course in Quality Control and Assurance. With the wealth of knowledge, experience, and passion I gained, I am a perfect fit for any company who wants to be a leader in product and process quality!

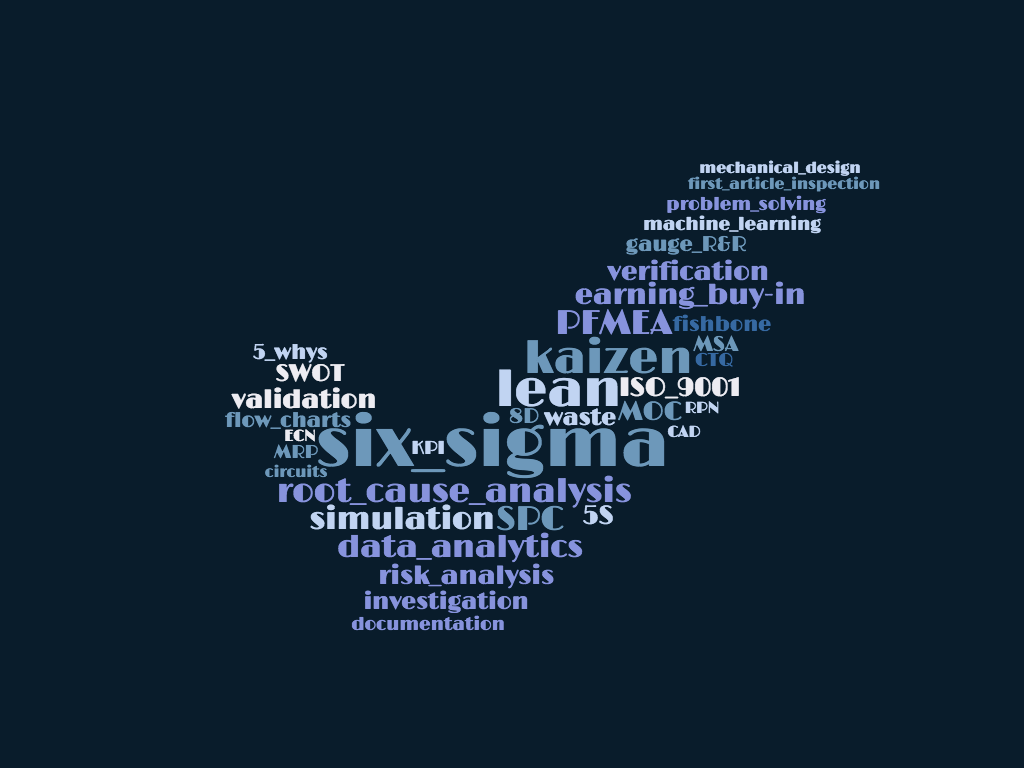

Quality Tools

While this list is not complete, here are a list of tools I have either education, experience, or both with:

Want to learn more? Check out my "Home" page or "About Me" page!